Japan is setting off a semiconductor factory construction boom

Before revitalizing the semiconductor industry and establishing domestic production infrastructure, Japan has a long way to go.

The past three decades have been regarded as the "lost three decades" for Japan's semiconductor industry, and the country's intention to make a comeback is now apparent.

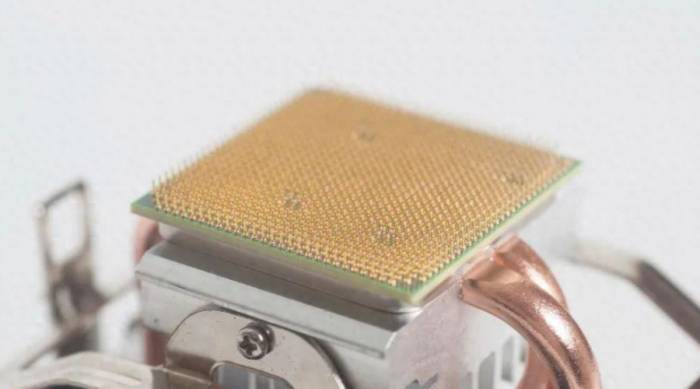

Semiconductors, used in a variety of products from electronic devices to artificial intelligence systems, play a key role in national economic security.

To ensure a stable supply of semiconductors, the government has allocated a total of 4 trillion yen in subsidies from fiscal year 2021 to fiscal year 2023 to help companies build semiconductor factories domestically.

Thanks to the huge subsidies, the industry is on the verge of a significant turnaround after decades of slump.

Last year, Rapidus, a chip manufacturer headquartered in Tokyo, announced the establishment of a factory in the northern city of Chitose in Hokkaido, with the aim of manufacturing the next generation of semiconductors in Japan.

Construction of the chip factory began last September and is currently underway at a rapid pace, aiming to achieve the company's goal of starting a prototype production line in April 2025 and beginning mass production in 2027.

Advertisement

Rapidus aims to mass-produce the most advanced chips with a circuit line width of 2 nanometers, which is an ambitious goal for Japan, which has lagged behind other countries in chip development. To acquire proprietary technology, the company has sent about 100 people to IBM's research base.In order to promote the revival of the industry, the government has decided to provide Rapidus with a subsidy of 330 billion yen. It also plans to offer additional financial support. Tetsuro Higashi, Chairman of Rapidus, stated, "I have no doubt that we will succeed."

"We absolutely must not fail in the (Rapidus) project," said Ken Saito, the Minister of Industry, at a subcommittee meeting of the Budget Committee of the House of Representatives in the Japanese Parliament last week.

Taiwan Semiconductor Manufacturing Company (TSMC), the world's largest semiconductor foundry, will begin operations at a factory to be built in Kikuyo Town, Kumamoto Prefecture, this year, marking the company's first factory in Japan. TSMC will construct another factory in the same prefecture.

The investment for these factories is approximately 3 trillion yen, with 120.8 billion yen to be provided as aid by the industrial sector. Japanese chipmaker Kioxia and U.S. Western Digital will invest over 720 billion yen to produce semiconductor memory in two joint venture factories in Kitakami City, Iwate Prefecture, and Shihwa City, Mie Prefecture.

U.S. chipmaker Micron Technology has decided to expand its factory located in Higashi-Hiroshima City, Hiroshima Prefecture. Japanese financial group SBI Holdings and Taiwan's Powerchip Semiconductor plan to build a factory in Oosawa Village, Miyagi Prefecture.

Despite the semiconductor industry itself being busy with factory construction, a shortage of engineers has emerged. Large semiconductor factories also require infrastructure-related work, including roads and industrial water supply. Saito expressed, "We still have a long way to go before revitalizing the semiconductor industry and establishing domestic production infrastructure," indicating the need for long-term assistance.

Statistics from the Ministry of Economy, Trade and Industry show that the number of employees in semiconductor manufacturers exceeded 190,000 in 1998, but due to industry decline, this figure dropped by 70% to 80,000 in 2020. The "Kyushu Semiconductor Talent Development Alliance," a government-led industry-academia-official organization in Japan, predicts that there will be an annual talent shortage of about 1,000 people in the semiconductor field in the Kyushu region over the next decade.

In Japan, where the aging population and low birthrate are intensifying, the number and proportion of the working-age population continue to decline, making high-tech talent even more scarce. Japanese media have pointed out that due to the explosive growth of the semiconductor industry, there is a clear trend of attracting high-skilled human resources with high salaries in Europe and America, and the challenge for Japanese companies is that, with the significant devaluation of the yen, the cost of hiring talent at high salaries has increased significantly, potentially lagging behind in the talent competition.

External support is needed.

Lithography machines were originally a field in which Japanese companies excelled. In the 1980s, they formed a monopolistic position in the lithography machine sector, especially Nikon, which once held more than 50% of the industry's share, and then Canon also entered the lithography machine market.According to a report by Gartner, an American IT market research and consulting firm, in the mid-1990s, Nikon and Canon held 70% to 75% of the global market share. ASML, a Dutch company founded in 1984, later took the lead by meticulously sourcing components from suppliers around the world to assemble photolithography machines. CNBC, the American consumer news and business channel, pointed out that ASML has been able to make significant strides in the field of EUV (Extreme Ultraviolet) photolithography machines, benefiting from investments and external technological cooperation with companies like Samsung, TSMC, and Intel, as well as establishing exclusive procurement relationships with hundreds of suppliers.

In contrast, Japanese companies like Nikon tend to favor self-sufficiency in research and development and component manufacturing, which leads to high development costs and relatively slower speeds. This has been seen as one of the main reasons for the failure of Japanese companies to enter the EUV photolithography machine market, and it is also related to the strategy of the Japanese government. Former Japanese Minister of Economy, Trade and Industry, Akira Amari, stated in a House of Representatives meeting that the Japanese semiconductor industry had the highest global sales in the 1980s, but its competitiveness continued to decline over the next 30 years because the government at that time failed to perceive global industry trends and did not implement appropriate policies.

The demand for EUV photolithography machines is urgent, and the Kishida administration is looking overseas. At the end of 2022, Rapidus signed a memorandum of technology cooperation with the Belgian research center for microelectronics (IMEC), and in March 2023, the two companies agreed to cooperate in the development of cutting-edge photolithography machine technology, including EUV photolithography machines. IMEC, as an independent research institution for semiconductor manufacturing, has been closely collaborating with ASML for about 30 years, jointly upgrading EUV photolithography machines and developing the next generation of High-NA (High Numerical Aperture) EUV photolithography machines. For Japan, there is a hope that IMEC will inject core technological strength.

The Japanese government led the development of the semiconductor industry in the 1980s with a self-reliance model, which essentially had no external technological assistance. However, Japan now realizes that relying solely on its own capabilities is not enough, and thus emphasizes the support of external technologies.

Leave a comment

it’s easy to post a comment